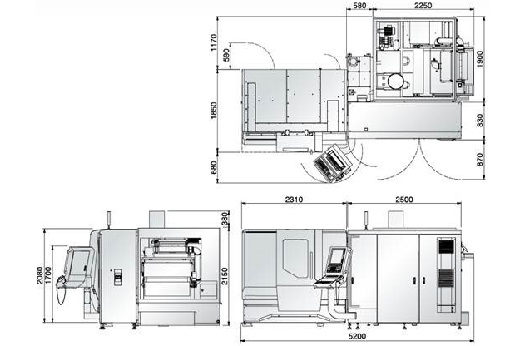

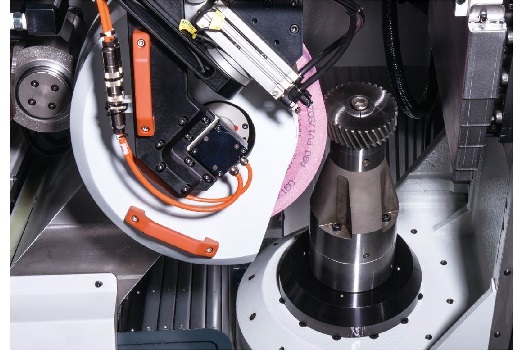

GVC-3020 CNC Continuous Generating Gear Grinding Machine is equipped with the most advanced SIEMENS CNC controller available and the high-precision electronic gear box module supplied by Siemens. Also integrated in the machine are an 10-axis close-loop servo control system and a direct drive motor such that all axes move simultaneously and very accurately.

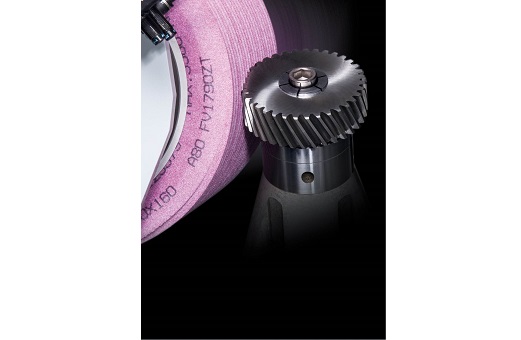

GVC-3020 is equipped with high-speed spindles. The speed of grinding wheel spindle can reach up to 80M/sec. Together they work in concert to increase gear production efficiency and accuracy. Meanwhile, the built-in automatic dynamic balancing system acts to reduce deviation caused by dressing or grinding.

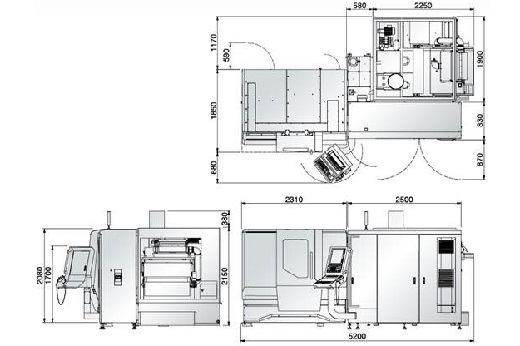

| GEAR SPECIFICATIONS | GVC-3020 | |

|---|---|---|

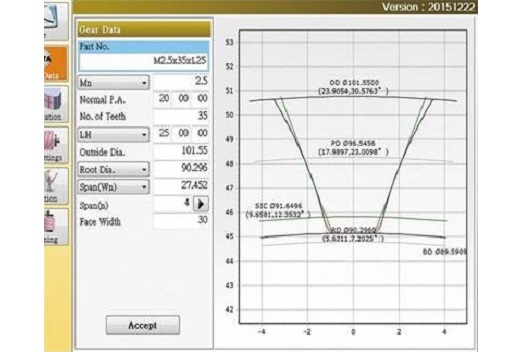

| Max. workpiece outside diameter | 300 mm | 11.8” |

| Min. workpiece root diameter | 10 mm | 0.3” |

| Max. module | M 5 | DP 5 |

| Helix angle | ±45° | |

| MECHANICAL SPECIFICATIONS | ||

| Max. slide travel for Z-axis | 200 mm | 7.8” |

| Drive power of workpiece spindle | 20 kW | 26 Hp |

| Max. table load (workpiece with fixture) | 50 kg | 110 lb |

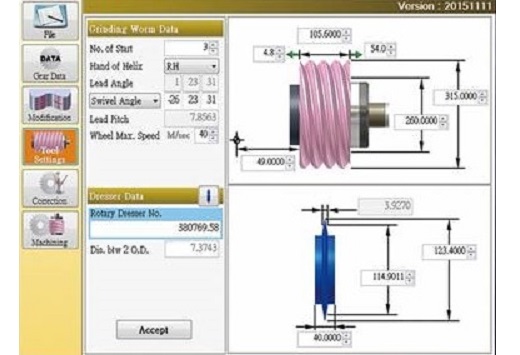

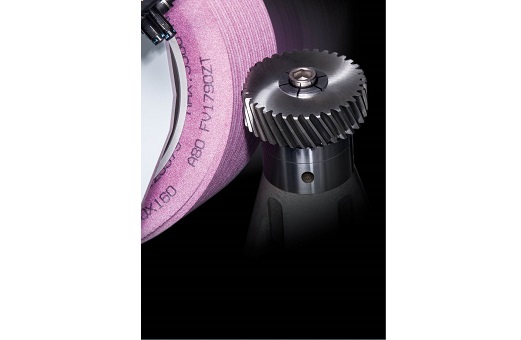

| GRINDING WHEEL SPECIFICATIONS | ||

| Min. /Max. Grinding wheel outside diameter | 220 mm / 275 mm | 8.6” / 10.8” |

| Max. grinding wheel thickness | 160 mm | 6.3” |

| Max. speed of grinding wheel | 80M/sec | |

| Drive power of grinding wheel | 25 kW | 33 Hp |

| Max. grinding wheel teeth number | 9 |

| N-axis | Grinding spindle |

|---|---|

| A-axis | Swivel Angle |

| B-axis | Grinding Spindle |

| C-axis | Workpiece Spindle |

| X-axis | Grinding Radial Slide |

| Y-axis | Workpiece Horizontal Side |

| Z-axis | Workpiece Axial Slide |

| A1-axis | Rotary Dresser Lead Angle Rotation |

| B1-axis | Rotary Dresser Spindle |

| X1-axis | Dressing Radial Slide |

| Y1-axis | Dressing Axial Slide |

| Z1-axis | Tailstock Axial Slide |