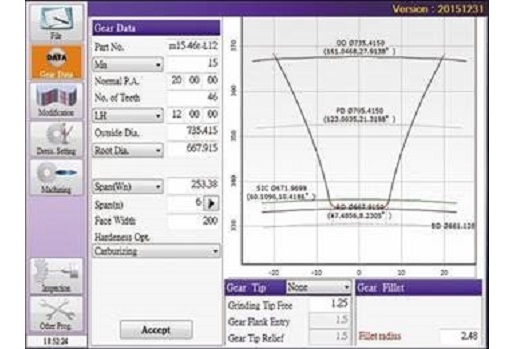

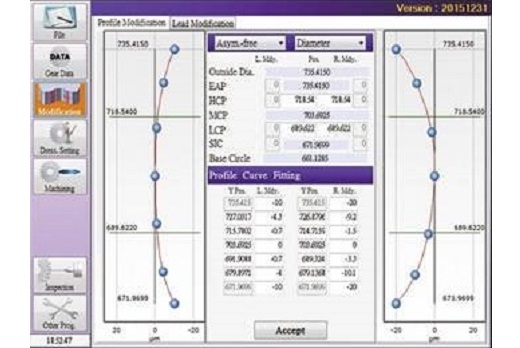

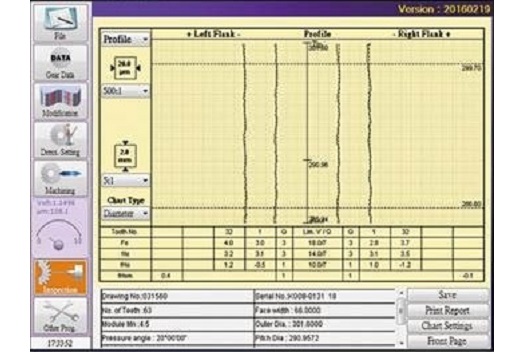

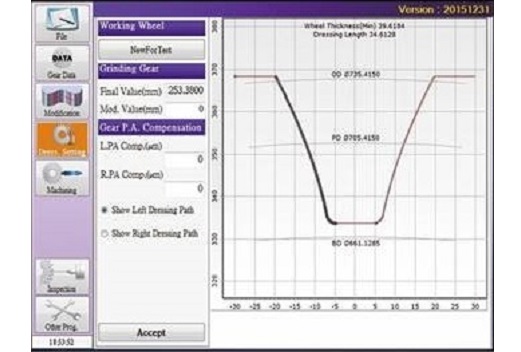

The GVP-8040 Vertical Gear Profile Grinding Machine applies the FANUC controller and high-speed grinding spindle;through the Matrix Precision-developed intelligent conversations window software, it can flexibly output the required tooth profile and grinding parameters. The workable machining workpieces include the involute gears, large-module hobs and cycloidal gears.

GVP-8040 applies the globally famous FANUC controller. It combines the direct drive motor and 8-axis close-loop servo system; each axis can simultaneously run to obtain a high-precision performance.

GVP-8040 is built in vertical construction, which enables mitigating the bending/deforming effect of large workpieces from gravity and building a more stable gear grinding process.

| MAIN SPECIFICATIONS | GVP-8040 | |

|---|---|---|

| Gear | ||

| Max. workpiece outside diameter | 800mm | 31.4” |

| Tooth range | 9~999 | |

| Min. workpiece root diameter | 50mm | 1.9” |

| Module | M2.0~M20 | DP12.7~DP 1.27 |

| Max. tooth depth | 45mm | 1.7” |

| Helix angle range | ±45° | |

| Hob cutter | ||

| Min. root diameter/Max. workpiece outside diameter | 50mm~350mm | 1.9”~13.7” |

| Max. flute depth | 55mm | 2.1” |

| Flute range | 1~99 | |

| Flute helix angel range | ±40° | |

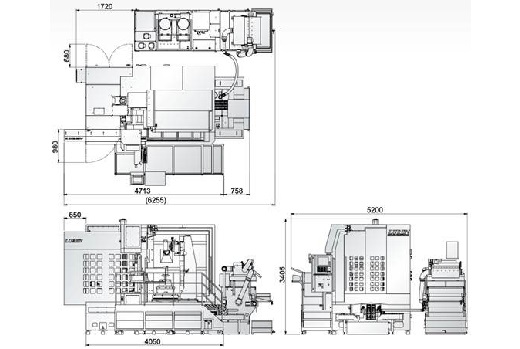

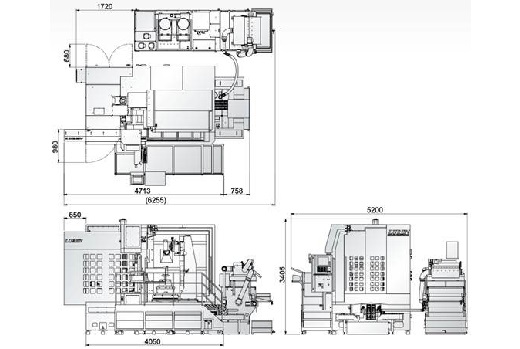

| MECHANICAL SPECIFICATIONS | ||

| Max. grinding slide travel (Y axis) | 400(450)mm | 15.7”(17.7”) |

| Max. workpiece slide travel (Z axis) | 500mm | 19.6” |

| Tailstock center height above rotary table | 600mm~1250mm | 23.6”~49.2” |

| Table diameter | 740mm | 29.1” |

| Max. table load (workpiece with fixture) | 2500 kg | 5500 lb |

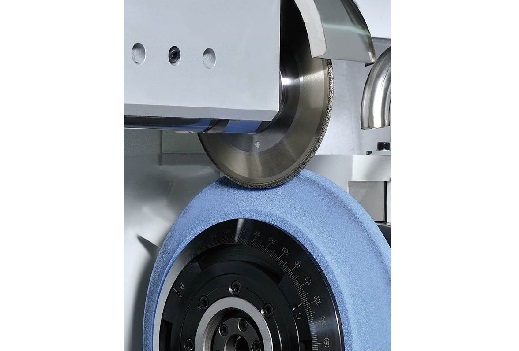

| GRINDING WHEEL SPECIFICATIONS | ||

| Min. dressable diameter of the grinding wheel Max. grinding wheel diameter | 260mm / 400mm | 10.2” /15.7” |

| Max. grinding wheel thickness | 70mm | 2.7” |

| Max. grinding spindle speed | 4000 rpm | |

| Drive power of grinding spindle | 15kW | 20Hp |

| N-axis | Grinding spindle |

|---|---|

| X-axis | Wheel axial slide |

| Y-axis | Wheel vertical slide |

| Z-axis | Workpiece radial slide |

| A-axis | Measuring arm swing |

| B-axis | Workpiece Indexing |

| C-axis | Wheel swiveling |

| S-axis | Grinding spindle |

| U-axis | Rotary wheel spindle |